We are proud to announce the completion of our restoration project, the Croce Astile, a Tuscan crucifix which was sponsored by the Washington, DC Chapter. Thanks to your generosity, beautiful artifacts like this will remain a vibrant example of the beauty and artistry of the Vatican Museums.

Final Restoration Report

The Croce Astile is part of the Baroque collection which became part of the Vatican Museums collection in 2007, thanks to the donation of Carlo and Lucia Barocchi. The work is the fruit of Tuscan silversmiths. According to the information that we have, it would seem that the cross, the crucifix, and the graft with the globe belong to different periods.

The cross is made of gold-plated, silver-plated copper alloy. What differentiates this work from the most common processional crosses is the lack of a wooden supporting element, replaced by a sheet of silver-plated copper alloy with the ends of the two orthogonal poly-lobed arms.

An iron bayonet, welded to the lower end of the longer arm, in turn, is in the socket of the silver element. The ten gilded frames, five on each side, give volume and importance to the cross and the riveted pins attach the two faces of the bearing plate.

On the front of the cross is the figure of Christ, realized in silver and of excellent workmanship. At the top is a traditional scroll and in the lower part above the poly-lobed tile is a skull. On the back there are no inserted figures. The laboratory only noticed the presence of a hook in the upper part.

The Intervention

The objective of the restoration targeted the removal of the dark areas that cover the greater part of the work. In particular, these areas cover the light of the small model of the realization of Christ finely realized by expert hands.

After the preliminary documentation of the cross, restorers moved on to the disassembly of all constituent elements. In order to do this, it was necessary to remove the old metal pins that held the parts together. Restorers then used polar solvents, such as acetone and ethyl alcohol, to remove the old protective layer and the layer of organic substances.

They removed the brown patina, probably composed of silver sulfides, by means of complexing agents and a mechanical action with micronized calcium carbonate and demineralized water. The degree of hardness of this product prevented in-depth action and therefore fully respected the patina of the silver. The laser welder (Mark-uno 7500) restored the detached parts. At the end of the cleaning process, all the parts were thoroughly rinsed with demineralized water. Then a dehydration process took place and the usual procedures followed.

At the end of the restoration intervention, there was an application of protective film (ZAPON in acetone 30% p/p) to keep the surface’s tone, light, and brightness as long as possible.

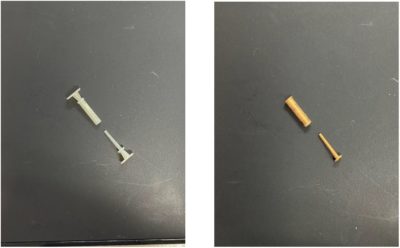

In the substitution of the old pins in metal, removed during the phases of the disassembly of the work, the laboratory realized through 3D software that the new pins are from two elements. After being molded in castable resin, the pins are of copper alloy casting.

This new assemblage system is important because it does not require a deconstruction of the cross, which will be helpful for eventual new restoration interventions in the future. Removing the old metal constraints

Removing the old metal constraints

Castable resin pin printing and the new pins made of copper alloy

Castable resin pin printing and the new pins made of copper alloy

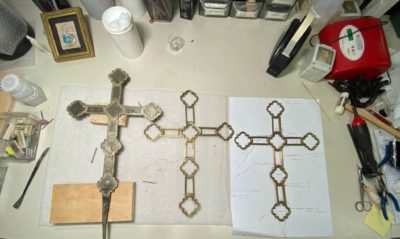

Constructed elements of the cross

Constructed elements of the cross

Front and back of the cross after the restoration

Front and back of the cross after the restoration

Posted on May 24, 2021